Imagination, Innovation & Indigenous engineering is at the core of Data Pattern’s Mechanical product design services. We are proud to push the limits to design and develop unique engineering solutions for advanced requirements in the fields of Defense, Military, Aerospace, Flight controls, ATR systems, Electronic warfare equipment, Naval, Radar, Laser Electro-optics; applications that demand stable functioning in extreme environmental conditions.

Data Patterns has a large engineering design group carrying out design of electronic packaging and complex mechanical parts specific to the application domain. The nature of the products designed can be broadly categorized as below:

- Cockpit displays

- Rugged military equipment – On-ground & Airborne

- Automatic test equipment

- VME & VPX modules

- Radar systems

- Naval systems

- Consoles

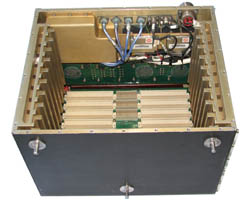

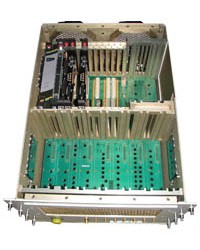

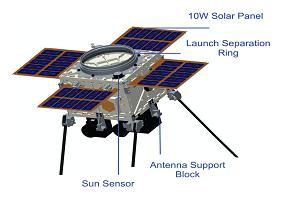

In general, we offer product design for Air & Conduction-cooled enclosures, large rack systems & consoles, and, gimbals & precision parts. We also create exacting In-cube electronic housings for space applications. All systems and products are designed and developed to conform to required international and military standards.

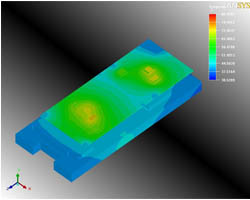

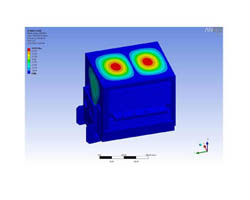

Our expertise includes thermal analysis, often with the need to meet MIL-STD specification; Thermal Design for Electronic Cooling Covers, Conduction Heat Transfer, Analysis and Flow analysis for identifying Hot Spots in PCB. We also employ Finite Element Analysis (FEA) to simulate field conditions prior to actualization. Our design offering encompasses 2D and 3D modeling from concept to completion.

We are able to create jigs and fixtures where required, for manufacturing and testing mechanical assembly, to specified weight ratios. Static and dynamic shock mounts are optimized to meet actual conditions, and for exceptional use cases as well. EMI, EMC compatibility is ensured with accurate calculations for selecting standard Honey Comb designs.

Our Structural Analysis expertise involves:

- Stress & thermal deflection under load

- Vibration and shock simulation and analysis

- Vibration Fixture

- Shock and Bump Fixture

- Compatibility with standard vibration tables

- High dampening and dynamic balancing

We can style the design with Corel Draw to enhance demo, and hence mutual understanding of scope with client, preempting need for rework. GD&T expertise is utilized for ensuring DFM and is implemented in the detailing. Use of Fit-Function checks to ensure proper dimensioning of product further promotes accuracy and ‘first-time-right’ results. Stack-up analysis is carried out using in-house capabilities to prevent cumulative errors in dimensions.

Simulation tools allow the design to be economically optimized. Using these tools the results can be predicted, even before having a prototype. Further, design optimizations can be done to estimate the budget on the product. All our mechanical products are built with healthy margins to brave the required physical conditions demanded of the product. Additionally, we reduce, if not eliminate, problems in cabling position and routing, and connector dimensions while translating from design to execution, by extending the use of ProE.

We are experts in a range of tools that enable the generation of a complete digital representation of the product being designed. In addition to the general geometry tools, there is also the ability to generate geometry of other integrated design disciplines, such as industrial and standard pipe work, and complete wiring definitions.

Our professionals are well-versed in design tools like:- Creo 2.0

- Autocad 2014

- E3 Cabling

- Ansys

Our tools support collaborative development as well. These range from conceptual Industrial design sketches, reverse engineering with point cloud data and comprehensive free-form surface tools.

Traceability to drawings is maintained to detect, correct or improve designs. We also offer traceability of raw material to the source where required. We can carry out optimum selection of material for the required IP, EMI and EMC use cases. Metallurgical testing of samples can also be performed as per client requirements.

Our continuously growing library of Risk Mitigation measures has been compiled for over two decades, and we can save time and cost for you with the lessons we have learnt. If you are in the market for an experienced and reliable manufacturer to realize your vision, working with you, and for you, with a stringent time and quality emphasis, it’s more than likely that we are the people who can deliver.

Air & Conduction-cooled Enclosures

|

|

|

|

|

|

|

|

|

|

Gimbals and Precision Parts

|

|

|

Thermal Analysis and Cooling Design

Strctural Analysis and Ruggediser Design

|

|

|

|

|