Cabling

Data Patterns has a separate cabling department, which produces all the cable assemblies, as well as carries out LRU and Rack level cabling integration activities

Infrastructure

- ESD (Electrostatic Discharge) complied workbenches

- Practicing 5S

- Team of Operators trained in IPC-WHMA-A-620

- Online Inspection

- Recommended tools for all connectors

- Usage of thermal strippers

- Calibration of tools

- Usage of Nail boards for offline harness preparation

- Harness tester for Continuity, Isolation and Insulation

- Special test like LCR Measurement using Harness tester

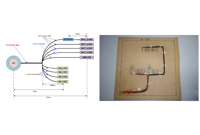

Capability

- EMI/EMC compatible cabling

- Reliable Internal system wiring

- Complex cabling including digital, analog, RF, etc.

- RF (Radio Frequency) cabling

- Multistrand wire and shielded cables, coaxial cables, rigid, Semirigid, flex and semiflex RF cables

- Crimp type and solder type, D type connectors, Micro D connectors, MIL D38999 connectors, 1553B connectors, EURO connectors, SMA (Sub Miniature A version), SMB (Sub Miniature B version) and BMA (Blind Mate A) connectors and splicing, special connectors like Gang connectors, etc.

Process

- Well established process

- Complying to IPC-WHMA-A-620 standard

- Pull test for Reliability checking of crimp contacts

- Calibration of tools and soldering stations

- Guidelines for special processes

- Traceability and Reliability